Photochemical etching (PCE) is a technology used in the manufacture of integrated circuits and other electronic devices. It uses a photosensitive material to remove material by using the energy of light. In 2023, we’ll look at how PCE will be used in manufacturing and how it will impact the industry.

What is Photochemical Etching?

Photochemical etching is a process that uses light to remove material from a surface. It is often used to create patterns or letters on glass or other materials. The process works by using light to break down the molecules of the material that we want to remove.

This process can be done in two ways: with a gas called etching gas and with a liquid called etching liquids.

With a gas, we use an acid or a base to create an environment that enables the light to break down the molecules of the material. With a liquid, we use water or another liquid as the etching liquid. We then expose the material to light, which breaks down the molecules and removes them from the surface.

How Does Photochemical Etching Work?

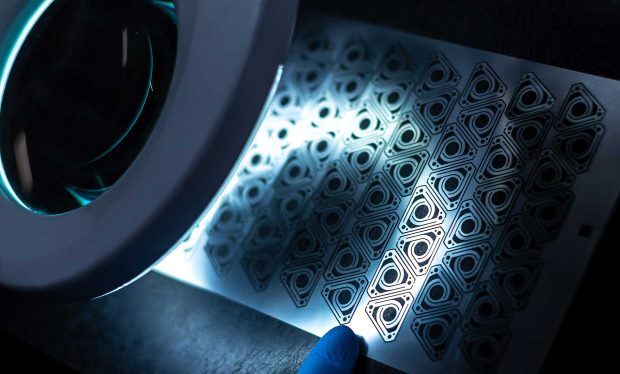

Photochemical etching (PCE) is a process used to create patterns or structures on a surface by removing material with light. PCE is used to create patterns on semiconductor wafers and other substrates.

The process begins by irradiating the substrate with ultraviolet light. This causes the atoms in the substrate to break down into their component atoms. The photons from the UV light then attack these new atoms, causing them to be removed from the substrate.

The removal of material can be done in several different ways. One method is called dry etching, which uses a gas such as xenon or hydrogen gas to remove material from the substrate. Another method is called wet etching, which uses a solution or liquid to remove material from the substrate.

PCE has many applications, including the production of semiconductor chips and MEMS devices. It is also used to create patterns on metals and other materials.

Benefits of Photochemical Etching

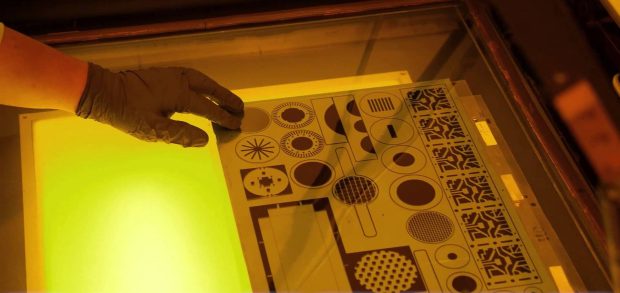

Photochemical etching (PCE) is a process that can be used to create patterns on a surface. It is similar to lithography, but it uses light instead of a chemical agent.

Benefits of photo etching include the ability to create intricate patterns and designs on a surface. PCE is also faster and more accurate than other methods of patterning, such as lithography.

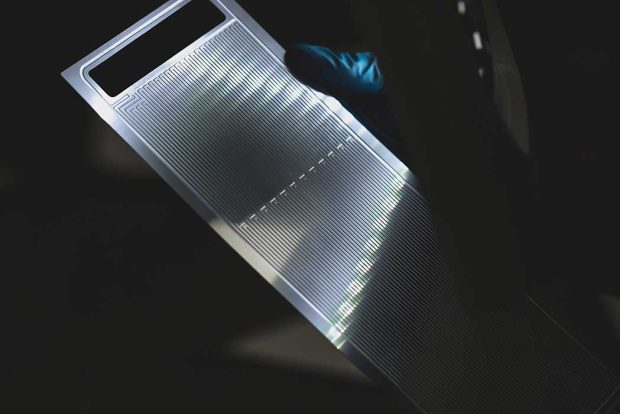

PCE can be used to create patterns on a variety of materials, including metals, plastics, and composites. It is also able to create patterns that are difficult or impossible to create using other methods.

One example of a pattern that can be created using PCE is a 3D printed object. By using light to guide the printing process, it is possible to create objects with complex shapes and details.

Challenges of Photochemical Etching

Photochemical etching (PE) is a process used to remove material from a surface. The main challenges faced in PE are the control of the reaction and the removal of the unwanted material.

In a PE process, light is used to break down materials on a surface. This process can be used to remove material from metals, plastics, and other materials. The main advantage of PE over other methods is that it can be used to remove material without damaging the surface.

PE is an effective way to remove material from surfaces. It has few limitations, and it can be used to remove a wide range of materials. Additionally, PE is relatively simple and cheap to use.

Photochemically Etched Cleaning Process

The photochemically etched process is a cleaning process that is used to remove residues from the surface of pc boards.

This process has been around for over thirty years and is still widely used today. The photochemical etching process uses a combination of two chemicals: an acid and a base, which are mixed together. The acid etches the surface and the base removes the acid residue.

The cleaning process uses UV light to activate the mixture, creating a chemical reaction that removes residues from the surface of pc boards. This reaction can be seen as bubbles on the surface of pc boards after they have been cleaned in this way.

Limitations and Drawbacks of Photochemical Etching Processes

The limitations of the photochemical etching process are that it is limited to organic and inorganic materials with a high surface energy. The drawbacks of this process include that, it is a complex process which requires expensive equipment, has low throughput, and can only be used for certain types of coatings. There are two types of etching processes. One is a reactive process and the other is an oxidative process.

• The reactive process uses strong oxidizing agents such as hydrogen peroxide, alkaline peroxide, or ozone to oxidize the surface being etched.

• The oxidative process uses metal oxides such as aluminum oxide, silicon dioxide and titanium dioxide to densify the surface being etched.

One of the disadvantages of the reactive process is that it is slow and can only etch a thin layer. On the other hand, the oxidative process is fast, but it cannot etch a thin layer. It can only make a rough surface because it densifies too much, making tiny pores in the surface which are visible under an optical microscope. However, the oxide surface of a piece of steel can be made to look matte, shiny, or reflective by applying a thin layer of nitride to the surface. The process for producing the oxide layer is called diffusion nitride and it is used to make light reflectors for cameras and TV screens.

Conclusion

Photochemical etching (PE) is a process that uses light to remove material from a surface. It’s often used in the manufacturing of electronic and optical devices, as well as printed circuit boards. PE uses specialized equipment to expose the substrate to an electron beam and then use a chemical solution to dissolve the material being removed.