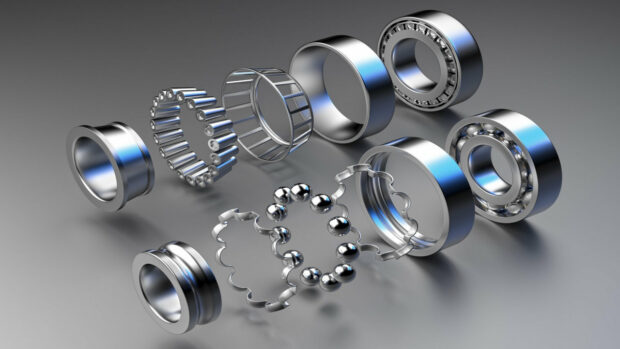

Bearings are the unsung heroes of the complex mechanical world, silently facilitating the smooth rotation and movement that drive modern technology. Because of their simplicity, bearings are sometimes disregarded as the essential components that reduce wear and tear and increase operating efficiency by counteracting friction. These compact yet powerful parts are available in a variety of forms, each designed for a particular use, from delicate instruments to heavy-duty industrial machines.

Bearings are the lifeblood of mechanical systems; they make motion smooth by offering a low-friction contact between moving elements. It becomes crucial to comprehend the subtleties of bearing kinds in this dynamic environment.

Each variation contributes differently to the harmonious mechanical composition, from the sturdy stability of roller bearings to the accuracy of ball bearings and the ease of use of plain bearings. Come along on a voyage through the complexities of bearings, learning about their many varieties and the vital role they play in the operation of the machinery that drives forward our contemporary world.

Most of you probably know where to get your bearings but not all of you know the best place for that, no matter what type or kind of bearing you are looking for. To see what they have for you today check out https://www.tuli-shop.com/bearings/take-up-housing-units.

We’ll examine the most common bearing kinds in this article and provide insightful advice to assist you in making wise choices in 2024.

Common Bearing types

1. Roller Bearings

A basic kind of bearings renowned for their robustness and load-bearing capability are roller bearings. Cylindrical, tapered, and spherical roller bearings are members of this family and are all excellent in their respective fields. Spherical roller bearings can accept misalignment and strong radial loads, whereas cylindrical roller bearings are best suited for radial loads. Tapered roller bearings can manage both radial and axial loads. To choose the best kind of roller bearing, take into account the unique requirements of your equipment.

2. Ball Bearings

Ball bearings are widely used because of their accuracy and capacity for smaller loads. Common variations include thrust ball, deep groove, and angular contact bearings. While angular contact ball bearings work well under mixed radial and axial stresses, deep groove ball bearings are better suited for radial loads. The primary purpose of thrust ball bearings is to support axial loads. The load distribution and equipment operating circumstances will determine which kind is best.

3. Plain Bearings

Plain bearings function by sliding rather than by rolling, and they are sometimes referred to as bushings or sleeve bearings. They are frequently more affordable and have a simpler style. Applications involving sluggish or fluctuating rotational motions are appropriate for plain bearings. The decision between plastic and metal-backed bearings is influenced by several elements, including load, speed, and ambient conditions.

4. Needle Bearings

A specific kind of roller bearing with thin, cylindrical rollers is the needle bearing. They are perfect for applications with limited space because of their small size and great load-carrying capability. In gearboxes, car transmissions, and other machinery where small size and accuracy are crucial, needle bearings are frequently utilised.

5. Ceramic Bearings

Compared to conventional steel bearings, ceramic bearings made of materials like silicon nitride or zirconia have benefits. They are lighter, more temperature-tolerant, and have better corrosion resistance. For some applications, such as high-speed machinery or hostile locations, the advantages of durability and efficiency may exceed the initial cost, although they might be more expensive.

Lubrication is the key – always choose quality!

For maximum performance and lifespan, appropriate lubrication is essential, regardless of the kind of bearing. High-quality grease is essential to reduce friction, dissipate heat, and protect against wear because these things tend to suffer if not lubricated properly and with quality grease for bearings.

Select a grease that is appropriate for the temperature range and operating circumstances of your equipment. Keep up with routine maintenance intervals, which include checking the grease levels and replacing them as needed. All of this will guarantee seamless functioning and prolong the life of your bearings, which are essential if you perform significant tasks and use pricey, high-quality equipment.

What to consider when choosing bearings?

1. Load Requirements

Think about the kinds and sizes of loads that your equipment may encounter. Different bearing kinds can support varied radial, axial, or combined load capacities. Determine if the application calls for bearings that can sustain high rotational speeds, severe loads, or both.

2. Operating Conditions:

Consider the operational environment and circumstances that your bearings may encounter. Extremes in temperature, contact with chemicals or moisture, and the presence of impurities can all have a substantial impact on a bearing’s performance and longevity. Select bearings made of materials and seals that are resistant to the unique difficulties presented by your working environment.

3. Speed and Precision Requirements

Bearings have varying capacities for handling varying speeds and accuracy levels. Choose bearings made to withstand high-speed rotation and accurate motion control if your machinery will be operating at these speeds. For instance, angular contact ball bearings are ideal in situations where speed and accuracy are essential.

4. Space and Installation Constraints

Examine the area that may be used for bearing installation and any limitations imposed by the general layout of your apparatus. Needle bearings or ceramic bearings are good options for situations that call for small, light solutions. Because misalignment can affect how simple a bearing is to install and maintain, think about whether the type of bearing can handle it.

5. Maintenance Requirements

Take into account the bearings in your application and their maintenance requirements. Certain types of bearings, including sealed or pre-lubricated bearings, offer longer maintenance intervals, while others may need more regular maintenance, like relubrication. Select a bearing type that complements your resources and maintenance plan.

In conclusion, you must take into account a variety of considerations when choosing the best type of bearing for your application, including weight, speed, available space, and climatic conditions. Keep up with the most recent developments in bearing technology, and don’t undervalue the significance of using high-quality grease to keep your bearings in good working order. You’ll be prepared to make wise judgements in 2024 and beyond if and when you need to, thanks to this article.